Building Better Biologics: A Q&A with Danielle Tullman-Ercek

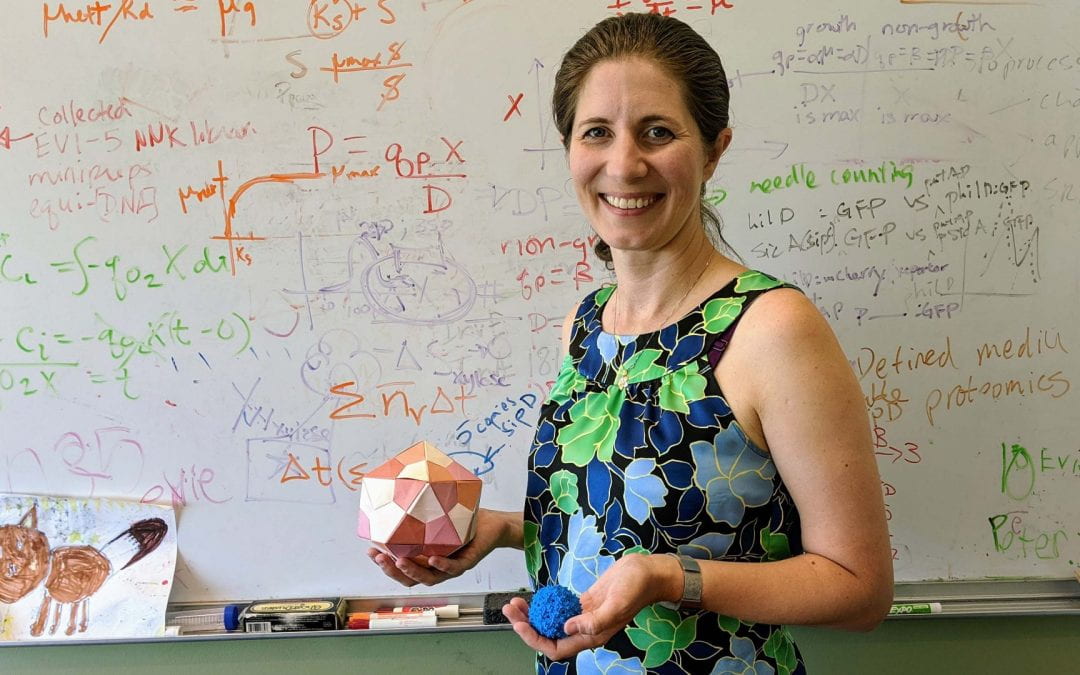

Like a master Lego® builder who constructs elaborate figures using tiny interlocking blocks, Chemistry of Life Processes Institute member Danielle Tullman-Ercek manipulates parts of bacteria and viruses to build new and better structures for drug delivery, diagnosis and vaccination. CLP recently caught up with Tullman-Ercek, Associate Professor of Chemical and Biological Engineering, and Director, Master of Science in Biotechnology Program, McCormick School of Engineering, to learn more about her research and what initially drew her to the field.

CLP: Before you came to Northwestern, what was the initial focus of your research?

Tullman-Ercek: I have been an associate professor in chemical and biological engineering at Northwestern since 2016. Before that, I was at UC Berkeley for seven years as an assistant professor in chemical and biomolecular engineering. Initially, my projects focused on how we can use biology to make more cost-effective fuels and chemicals for commercial use to reduce dependency on petroleum. We started with the basics: How can we use an organism to convert any substrate to a desired product, such as a fuel?

All my early work focused on how to control what goes into and out of the cell. It’s sort of like having a factory with no doors until you figure out the ‘in and out’ processes. Even though it is important that the factory makes the product you want, it is also really important that you can get the product out of the factory. We were optimistic about this approach because cells already have the machinery to control what goes in and out. We just had to learn the rules and manipulate those cellular machines.

We use techniques to manipulate proteins, the workhorses of the cells. They carry out the reactions and act as gatekeepers that sit in the membrane and control what is going across these boundaries. To control what goes in and out of the cells, we change the proteins that are already there, either by changing what they allow through, or changing how many of them are present. When the industry as a whole pivoted towards using biological organisms to make more sustainable products with higher value than fuels, we also began thinking about different ways to make chemicals, drugs and pharmaceutical products more cost effective.

CLP: Since coming to Northwestern, what projects are you working on?

Tullman-Ercek: When I came to Northwestern and became part of CLP, I started interacting with a lot more scientists that are interested in human health. I had been focused on getting things out of bacteria, but it’s a similar process to figure out how to get a drug into specific cells.

We spent quite a bit of effort in the first couple of years here on using virus-like particles because viruses are great at getting into cells in the body. Viruses also have a unique property in that they protect the cargo inside of them. Normally, that cargo is just the viral genome, which gives instructions to the cell to make more copies of the virus, but we can replace that with other things. It doesn’t have to be instructions: it can be a drug molecule, an imaging agent, or a signaling molecule. For example, we could potentially use these virus-like particles, load them up with an MRI contrast agent, and see where the cells that we are targeting are found in the body.

We start with natural building blocks, virus particles that already exist—these particles are basically the shell of the virus without its genome. We call it a particle because it’s just a carrier and not a virus anymore. It’s sort of like a naturally built Lego® with this really elaborate geometric structure, but we’re trying to figure out how we can change those building blocks a little bit to target a particular cell type, or change the size, and still form this beautiful geometric stable structure that protects its cargo.

Our methods have been working really well and giving us an unprecedented amount of information about how these building blocks assemble into the particles. We focused on one virus particle at first, and are trying to transition that into several other particles of different sizes, shapes and properties because there is not going to be a one-size-fits-all kind of carrier.

We noticed that these shells or carriers have pores that may allow us to control what is going into and out of them. Not only can we control where these are going in the body and what cells they are going into, but we can also potentially control the rate and the identity of things that go out of them. We can load them up with different therapeutics or have both a diagnostic agent and a therapeutic agent. We also look for ways to target and break them apart to kill pathogenic bacteria.

We are also working on turning these into vaccine carriers. Let’s say you want to have a vaccine against a particular bacterial infection. You would need to develop a way to trigger immunity against the sugar chains on the surface of that bacteria. The sugar chains are like fingerprints for the bacteria. Vaccines work by putting in a harmless version of what you want the body to be immune to, but you will not get an immune response just by injecting sugar chains in the body. You have to put them on a carrier that will help trigger the immunological response that you want. We think these virus particles can make excellent vaccine carriers since we can decorate the surface with whatever we want to have an immune response to and it would be completely benign because it’s just a shell— a scaffold really.

CLP: What diseases might these drug/imaging carriers target?

Tullman-Ercek: As a first pass, I would say diseases that can be treated through the bloodstream, such as certain types of cancers and heart disease. There is a good chance that we also can use them for inflammatory gut diseases, sepsis, or any kind of salmonella or food-based pathogens. We could also use them as an immunotherapy, or a more advanced targeted chemotherapy. We are trying to use these carriers in all the different ways that nature does, but first we have to learn the rules for those processes. I am very interested in the fundamentals. I want to be able to develop the technology from this basic understanding so that it can be applied to a whole slew of different diseases.

CLP: What other projects are you working on?

Tullman-Ercek: About a third of my lab works on the manufacturing of proteins. A number of products in everyday life are made out of protein, from the stain-fighting enzymes in laundry detergents to materials such as silk. Some proteins are even capable of functions we cannot do well with non-biological materials. For example, there are proteins that mediate adhesion under water, which could be useful in medicine, or in marine applications. We could also use protein to make sutures, which are essentially devices that are implanted in the body, degrade naturally and do not have any harmful side effects. Importantly, many of the top 10 drugs on the market are protein-based— important medications such as insulin and growth hormones.

Protein-based drugs are different than aspirin or Tylenol or small molecule drugs. To make protein-based drugs, you have to use an organism. You can’t just make them synthetically in a test tube. The problem is that organisms make all sorts of proteins to keep their life processes going, and it is hard to separate these proteins from the ones we want to mass produce. So, we work on using bacteria to make the protein, selectively identify the protein product we want, and secrete these protein products out of the cell, away from all the other cellular proteins. However, this process is not yet as cost effective as we like. The other problem is that we don’t make as much of the desired protein as we would like. The metric that we use is grams-per-liter. You need at least one gram-per-liter to be able to compete with other industries, preferably, 10 grams-per-liter. While the system that we are using worked in principle, it was producing about a million-fold less than what we needed at the time we started this project.

We have spent 10 years now working on this problem and are now up to a half a gram-per-liter, which is several orders of magnitude more than when we started. We’re almost there— right on the cusp of being able to commercialize it. We achieved this with lots of help from the core facilities here. It’s truly a team effort worldwide even to figure out how to manipulate these systems to make the protein we want. Now that we are so close, we are working on provisional patents for all of the technology we have developed.

CLP: What drew you to this field and to Northwestern?

Tullman-Ercek: I was always interested in science in general. I was also really good at math and did well in science, but I didn’t really—and this is hard to admit in a public form— but I hated science lab. It was boring. You are doing experiments that had been done thousands of times by other students all over the world and there was always a right answer, known to your teacher already. So, I didn’t really think I wanted to do experimental science for my career.

When I was in college [Illinois Institute of Technology], I majored in chemical engineering – math and science – and I did more theoretical and computational research while there. That was fine, but I was in a lab that was a mix of both computational and experimentalists and the experimentalists looked like they were having more fun, which baffled me because I thought that was the boring part.

When I went to graduate school [University of Texas], I chose to join a lab that studied proteins. My project was completely experimental and I loved it because it was a totally different experience trying to answer a question that nobody has ever answered and to design experiments to answer that question. It was a puzzle and a lot more fun than just doing a protocol. That is when I actually fell in love with science. I remember when I first figured out the joy of science: I had spent six months trying to make a particular construct and failed repeatedly until one day, when I read a note about the method I was using in an obscure paper and figured out why it wasn’t working. Everything fell into place and it felt so great. When you get through that, it’s exhilarating and sort of addictive. One nice result can make it all worth it.

CLP: How has being a member of the Chemistry of Life Processes Institute helped advance your research?

Tullman-Ercek: Before agreeing to move to Northwestern, I insisted on joining CLP because I wanted to be able to interact with chemists, biologists and engineers. That has turned out even better than I imagined with all the new collaborations and project directions I have now, most of which came from talking to other faculty or students in the hall, or at a CLP meeting. But there are other advantages, as well. When I visited, I got to tour core facilities and they blew me away. Seeing the capabilities here and the availability of the cores—there was no four-month waiting list to use a piece of equipment, or hoping at two in the morning that somebody would give up their time on the equipment because their experiment failed. It was eye opening.

It is one thing to have the equipment available in core facilities and it is another to have experts helping to guide the work. The scientists running the core facilities are just so knowledgeable and engaged in working with you to make sure that you are getting the most out of that experience. Some of the work that we have done has been so much better with their help. We include them as authors on our papers because they are helping design experiments. That’s not something that standard at other places. That is really transformational.

by Lisa La Vallee